Introduction

Efficient container handling is the backbone of global logistics, enabling the safe and swift movement of goods across ports, warehouses, and transportation networks. This guide explores the essential equipment used for container handling, their applications, and how to choose the right tools for your operations.

Key Types of Container Handling Equipment

1. Container Spreaders

Container spreaders are specialized lifting devices that attach to cranes or forklifts to securely grip and lift containers. They come in multiple configurations:

- Fixed Spreaders: Designed for standard-sized containers (e.g., 20ft or 40ft).

- Telescopic Spreaders: Adjustable arms for mixed container lengths (20ft–45ft).

- Hydraulic Spreaders: Ideal for heavy loads and precision lifting.

Applications: Ports, intermodal yards, and manufacturing facilities.

2. Container Lifting Slings and Rigging

Slings and rigging systems distribute weight evenly during lifts. Common types include:

- Chain Slings: Durable and heat-resistant for heavy-duty operations.

- Wire Rope Slings: Flexible and corrosion-resistant for marine environments.

Safety Tip: Always verify load capacity and compliance with ISO 17712 standards.

3. Container Moving Carts and Skates

- Steerable Carts: Manual or electric carts with swivel casters for indoor container transport.

- Load Moving Skates: Modular systems for relocating containers in tight spaces.

Example: Tandemloc’s all-terrain carts with pneumatic tires handle uneven surfaces.

4. Forklift Attachments

Specialized forklift accessories enhance container handling:

- Container Forks: Reinforced forks for lifting ISO containers.

- Side Shifters: Adjust loads horizontally for precise placement.

Case Study: Caldwell Lifting Solutions’ hydraulic drum trucks streamline warehouse operations.

5. Overheight Frames

Overheight frames extend the lifting capacity of spreaders for oversized containers (e.g., refrigerated or open-top units).

How to Choose the Right Equipment

1. Assess Load Requirements

- Weight: Match equipment capacity to container weight (e.g., 20–60 tons).

- Dimensions: Telescopic spreaders adapt to variable lengths, while fixed models suit uniform sizes.

2. Evaluate Environmental Conditions

- Indoor Use: Electric or manual equipment with noise reduction.

- Outdoor Use: Corrosion-resistant materials like galvanized steel.

3. Prioritize Safety Features

- Automatic twist locks for secure grips.

- Overload sensors and emergency stop systems.

4. Consider Automation

- Semi-automatic spreaders reduce labor costs in medium-volume operations.

- Fully automated systems handle 50+ containers/hour in high-throughput ports.

Industry Applications

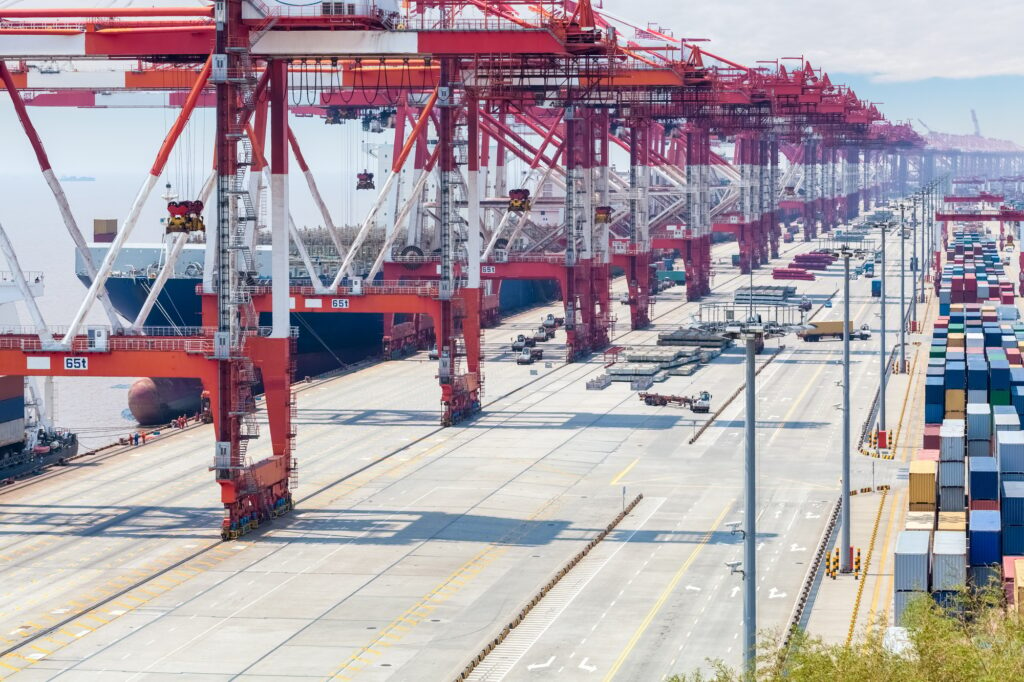

1. Ports and Terminals

- Straddle Carriers: Mobile gantries for stacking and transporting containers.

- Ship-to-Shore Cranes: Pair with spreaders for rapid vessel unloading.

2. Rail and Trucking

- Container Lifting Lugs: Attach to railcars for secure fastening.

- Articulated Spreaders: Adjust to uneven truck beds.

3. Warehousing

- Stacker Trucks: Vertical storage optimization.

- Pallet Trucks: Move smaller containerized loads efficiently.

Maintenance Best Practices

1. Routine Inspections

- Check wire ropes for fraying monthly.

- Lubricate hydraulic systems every 500 operational hours.

2. Cost-Effective Upgrades

- Retrofit older spreaders with IoT sensors for predictive maintenance.

- Replace twist locks every 2–3 years to prevent failures.

Future Trends in Container Handling

1. AI-Driven Equipment

- Predictive analytics optimize maintenance schedules and reduce downtime.

2. Sustainable Solutions

- Solar-powered spreaders and energy-efficient hydraulic systems.

Conclusion

From spreaders and slings to forklift attachments, the right container handling equipment ensures safety, efficiency, and scalability in logistics operations. Partner with trusted suppliers like Lifting Equipment Store USA for certified, durable solutions tailored to your needs.

Need Expert Advice?

Explore our container lifting equipment collection for industry-leading tools.