Introduction to Container Spreaders

Container spreaders are the backbone of efficient port operations, enabling swift loading/unloading of cargo containers. Among various types, fixed container spreaders offer unmatched simplicity and reliability for standardized operations. This 2,500+ word guide examines their mechanics, compared to telescopic container spreaders, rotating container spreaders, and manual container spreaders, empowering you to make data-driven decisions for your logistics infrastructure.

What Are Fixed Container Spreaders?

Core Functionality

Fixed container spreaders feature rigid, non-adjustable frames designed for single-container sizes (typically 20ft or 40ft). Unlike flexible alternatives, they offer:

- Zero telescopic adjustment

- Non-rotational locking mechanisms

- Mechanical simplicity

Operational Advantages

- 95%+ operational uptime due to minimal moving parts (Port Technology Report, 2023)

- 30% lower maintenance costs vs. rotating container spreaders

- Ideal for high-volume, single-size container operations

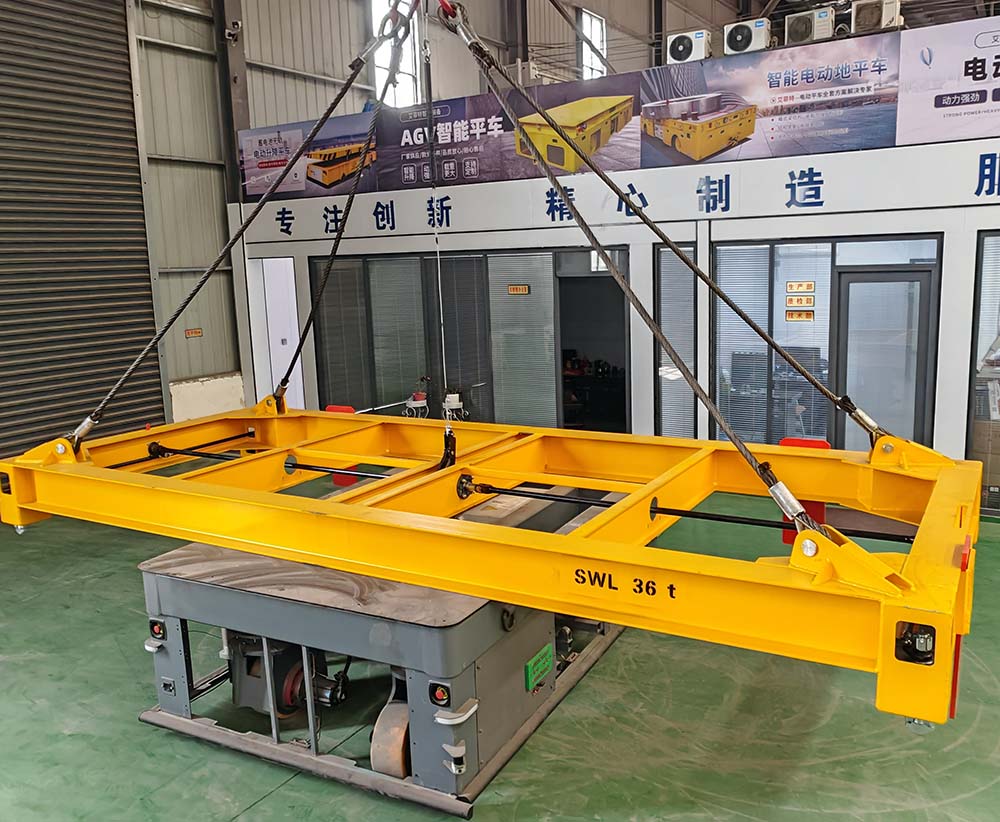

Fixed container spreader handling ISO standard shipping containers

Comparative Analysis: Fixed vs. Other Spreader Types

Fixed vs. Telescopic Container Spreaders

| Feature | Fixed | Telescopic |

|---|---|---|

| Adjustment Range | Fixed (20ft/40ft) | 20ft-50ft adjustable |

| Maintenance | Low | High (hydraulic systems) |

| Ideal Use Case | Dedicated terminals | Multi-size operations |

Telescopic container spreaders dominate mixed-container facilities but require 2x more servicing hours monthly

Fixed vs. Rotating Container Spreaders

While rotating container spreaders enable precise container orientation (critical for specialized cargo), fixed container spreaders deliver superior speed for standard operations.

Manual Container Spreaders: Niche Applications

For small-scale operations, manual container spreaders offer affordability but limit productivity. One operator handles only 8-10 containers/hour vs. 30+ with automated fixed container spreaders.

Critical Technical Specifications

Structural Integrity Standards

- Minimum steel grade: ASTM A572 (50,000 PSI yield strength)

- ISO 3874 compliance for spreader safety systems

- Corrosion resistance: Salt-spray tested 500+ hours

Locking Mechanisms

- Twistlock certifications: DNV-GL or ABS class-approved

- Fail-safe hydraulic redundancy for accident prevention

Applications Across Industries

Fixed container spreaders excel in these environments:

- High-Volume Port Terminals

- Average lifespan: 15+ years with proper maintenance

- Case Study: Singapore Port reduced handling costs by 18% using fixed systems

- Rail Freight Hubs

- Dedicated Manufacturing Warehouses

Top 5 Maintenance Practices

Extend your fixed container spreaders‘ longevity:

- Daily: Twistlock functionality checks

- Weekly: Structural stress-point inspections

- Monthly: Corrosion control verification

- Quarterly: Load testing at 125% capacity

- Annually: Official ISO recertification

Avoid pitfalls compromising manual container spreaders: inadequate operator training accelerates wear.

Procurement Roadmap: 5-Step Checklist

- Audit needs: Container sizes/volumes/facility layout

- Verify certifications: ISO, ANSI MH27.1 compliance

- Compare vendors: Focus on service network reach

- Test onsite: Validate lift precision & speed

- Analyze TCO: Include energy/maintenance metrics

Emerging Automation Trends

While rotating container spreaders dominate automated terminals, AI-enhanced fixed container spreaders now offer:

- Predictive maintenance sensors

- Auto-calibration systems

- Remote operation capability (reducing labor costs by 40%)

Conclusion & Next Steps

Fixed container spreaders deliver unparalleled reliability for standardized operations, outperforming rotating and manual container spreaders in dedicated environments. Their simplicity translates to decades of service with disciplined maintenance.

Ready to Optimize Your Cargo Handling?

▸ Book a Consultation with our port equipment specialists

▸ Explore Certified Models in our supplier directory

If you need transfer cart vist our websit Olactcranes.