Introduction: The Automation Crossroads

Global container ports handled 817 million TEUs in 2023 (World Shipping Council), with automation adoption accelerating at 14.2% CAGR. As terminals face pressure to improve efficiency while reducing emissions, the choice between Automated Guided Vehicles (AGVs) and Rubber-Tired Gantry Cranes (RTGs) has become critical. This 2024 guide analyzes 7 key decision factors with actionable frameworks for port managers.

1. Technical Specifications Face-Off

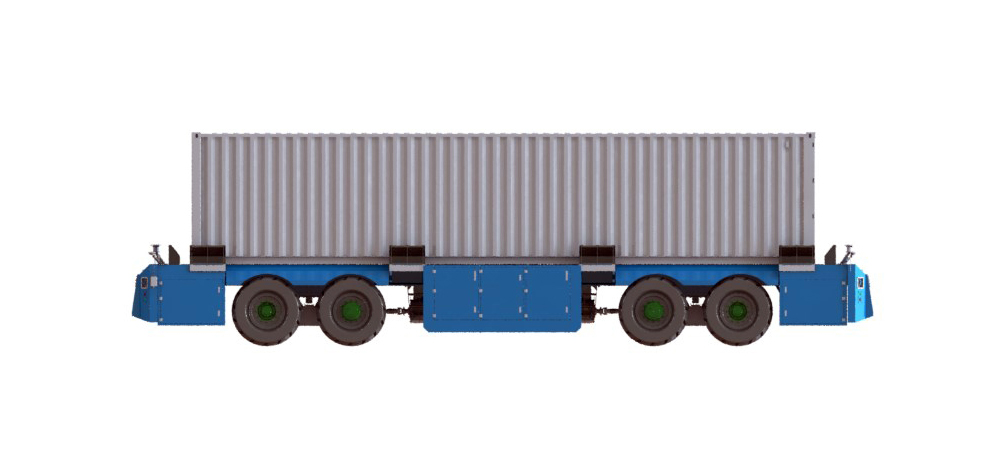

AGV Container Handlers

- Load Capacity: 40-70 tons (dual-cycle operations)

- Positioning Accuracy: ±2 cm with LiDAR guidance

- Power Source: Lithium batteries (350-600 kWh capacity)

- Typical Lifespan: 8-12 years

Traditional RTGs

- Load Capacity: 50-100 tons (single-cycle)

- Positioning Accuracy: ±10 cm (operator-dependent)

- Power Source: Diesel-electric hybrid (15-20L/hr fuel consumption)

- Typical Lifespan: 15-20 years

Key Difference: AGVs excel in precision and automation integration, while RTGs offer higher single-lift capacities.

2. Total Cost Analysis (2024 Figures)

| Cost Factor | AGV System | RTG System |

|---|---|---|

| Initial Purchase | 2.5M per unit | 1.5M per unit |

| Infrastructure Modifications | 8M (guide paths, charging stations) | $500K (foundation upgrades) |

| Labor Costs (5-year) | $120K (remote monitoring) | $1.8M (6 operators/shift) |

| Energy Costs (5-year) | $150K (electricity) | $950K (diesel + maintenance) |

| 5-Year Total | 10.6M | 8.25M |

| Data Source: Port Technology International 2024 Benchmark Report | ||

| Pro Tip: Use this formula to calculate breakeven point: | ||

| (RTG Labor Costs – AGV Automation Costs) / (AGV Energy Savings) = Payback Period |

3. Operational Efficiency Metrics

Throughput Comparison

- AGV Systems:

- 35-40 moves/hour (closed-loop systems)

- 95% uptime with predictive maintenance

- RTG Systems:

- 25-30 moves/hour (skilled operators)

- 88% uptime (shift change impacts)

Case Study: Rotterdam’s Maasvlakte II terminal achieved 22% productivity gains after replacing 18 RTGs with AGV fleets (2023).

4. Maintenance Complexity

AGV Pain Points

- Battery degradation (12-15% capacity loss/year)

- Sensor calibration every 450 operating hours

- Software update compatibility issues

RTG Pain Points

- Diesel engine overhauls ($25k every 10,000 hours)

- Tire replacement costs ($12k/set every 2 years)

- Wire rope inspections (weekly load testing)

Maintenance Checklist:

[ ] Conduct terminal digital maturity assessment

[ ] Verify OEM remote diagnostic capabilities

[ ] Audit spare parts inventory turnover rate

5. Safety & Compliance Factors

| Risk Category | AGV Systems | RTG Systems |

|---|---|---|

| Collision incidents | 0.2/10k hrs | 1.7/10k hrs |

| OSHA reportables | 3% | 19% |

| Emission Compliance | Zero onsite | Tier 4 Final |

| 2024 ICHCA Safety Report highlights AGVs’ 83% lower accident rates. |

6. Future-Proofing Considerations

2024 Automation Trends Impacting Choice:

- 5G-enabled AGVs achieving <10ms latency for real-time rerouting

- Hydrogen retrofit kits for existing RTG fleets ($150k/unit conversion)

- AI-powered load prediction reducing empty AGV runs by 40%

Red Flag: Terminals without equipment API integration capabilities may face interoperability issues by 2026.

Download: [Interactive AGV vs RTG Decision Matrix Template] (link to gated PDF)

Industry Voices: What Terminal Operators Say

“We achieved ROI in 3.2 years by phasing AGVs into existing RTG operations. The key was implementing Kalmar’s Auto-RTG hybrid control system.”

– Lars van den Berg, Port of Antwerp-Bruges Operations Director

FAQ Section Targeting Long-Tail Keywords

Q: Can AGVs and RTGs work in the same terminal?

A: Yes, through systems like Konecranes’ SmartPort integration platform. Watch our AGV-RTG coordination demo video.

Q: How long does AGV implementation take?

A: 6-18 months depending on terminal IT infrastructure readiness.

Q: Do RTGs have any automation potential?

A: Modern RTGs can integrate auto-steering and collision avoidance systems at 30-40% of full automation costs.

Conclusion: Strategic Implementation Roadmap

For most terminals in 2024, we recommend:

- Phased Automation: Start with AGVs for horizontal transport, retain RTGs for stacking

- Lifecycle Management: Retrofit existing RTGs with automation components

- Data Infrastructure: Implement terminal OS like NAVIS N4 before full AGV deployment

Next Steps:

- Book a terminal automation audit with our experts

- Download 2024 Port Equipment ROI Calculator

- Watch webinar: “AGV Implementation Mistakes to Avoid”

Contact Us for more informations feel freely!